Optimal Baking Pan Performance through Collaboration

Achieving optimal bake characteristics and operational efficiency is essential for bakeries aiming to deliver high-quality products consistently. A leading Australian bakery faced challenges with their existing aluminized steel baking pans, including uneven baking results, excessive energy consumption, and limited production capacity. Seeking a solution, they partnered with American Pan to develop a custom-engineered pan tailored to their specific operational needs. This collaboration not only addressed their immediate challenges but also led to remarkable improvements in baking performance and operational efficiency.

Identifying Challenges and Providing Solutions

One of the main challenges the bakery was experiencing with their current pans was that baking characteristics varied between the loaves on the edges of the set versus the loaves baked in pans located in the middle of the set. The loaves baked in the pans on the ends were a much lighter color and differed in bake texture. Another challenge is that energy costs continue to increase and the bakery was looking for ways to decrease energy consumption and further their sustainability goals while also keeping up with increased demand.

The existing 4 x 4 strap set used 22gauge aluminized steel for the individual pans and a solid 18gauge aluminized steel bumper and strap. After a thorough design review and multiple discussions, the collaborative efforts culminated in the development of a pan set using ePAN® materials and additional unique design features:

- 26gauge high strength aluminized steel pan construction: Lightweight yet durable, and used 30% less material than the standard aluminized steel design.

- 24gauge high strength aluminized steel pan strap: Ensured structural integrity and longevity.

- 16gauge bumper with air circulating holes: Promoted even heat distribution, leading to consistent baking results.

The Value of Partnership and Operational Insight

American Pan distinguishes itself by fostering strong partnerships with bakeries, emphasizing the importance of understanding each bakery's unique processes and challenges. This approach ensures that the solutions provided are not only technically sound but also that they seamlessly integrate into existing operations. By engaging closely with the Australian bakery, American Pan's team was able to observe firsthand the specific issues faced, from handling inefficiencies to inconsistent bake quality.

The bakery team was also very invested in the process and enlisted a team from the bakery to make incremental changes in the baking process to develop the optimal process. For example, they made changes to oven temperatures and baking times and monitored results through data, photos, and videos.

This collaborative effort allowed for the design of a baking pan that directly addressed the bakery’s challenges, showcasing the profound impact of a partnership built on operational insight.

Source: ©Bundy Baking Solutions

Source: ©Bundy Baking Solutions Key Performance Enhancements

The implementation of the custom-designed ePAN® led to several significant improvements:

- Bake Quality and Consistency

- Improvement: Uniform color and bake characteristics of all loaves.

- Impact: Consistency not only enhanced product quality but also bolstered customer satisfaction and trust.

- Optimized Pan Weight for Better Handling

- Improvement: The ePAN® was 21% lighter than the previous pan set (42 lb. vs. 53 lb.).

- Impact: Easier handling for bakery employees and equipment, improving ergonomics and reducing strain during production shifts. Less damage when stacking pans, extending the life of the pan.

- Faster Baking Time

- Improvement: Baking time decreased by 30 seconds per batch.

- Impact: Increased production cycles allowed for higher output and better resource utilization.

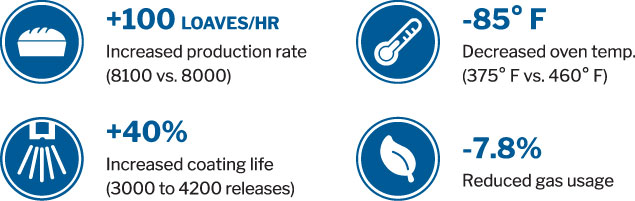

- Increased Production Capacity

- Improvement: Production rose by 100 loaves per hour (8100 vs. 8000 loaves).

- Impact: Enhanced throughput contributed to greater profitability and market competitiveness.

- Lower Oven Temperature

- Improvement: Required baking temperature decreased by 85°F (375°F vs. 460°F).

- Impact: Consistent baking quality was achieved alongside significant energy savings.

- Longer-Lasting Coating

- Improvement: Lower oven temperature extended DuraShield® coating release life by 40%. (3,000 releases to 4,200 releases)

- Impact: Reduced frequency of recoating needed, lowering maintenance costs and downtime.

- Reduced Gas Consumption

- Improvement: Gas usage declined by 7.8%.

- Impact: Lower energy costs and a reduced environmental footprint aligned with sustainability goals.

Source: ©Bundy Baking Solutions

Source: ©Bundy Baking Solutions Conclusion

The collaboration between the Australian bakery and American Pan underscores the transformative impact of partnerships grounded in a thorough understanding of operational dynamics. By developing a custom-engineered baking pan, the bakery realized substantial improvements in efficiency, energy consumption, and product quality. This case study highlights the importance of choosing partners who prioritize tailored solutions, demonstrating that such collaborations can lead to superior performance and a competitive edge in the baking industry.