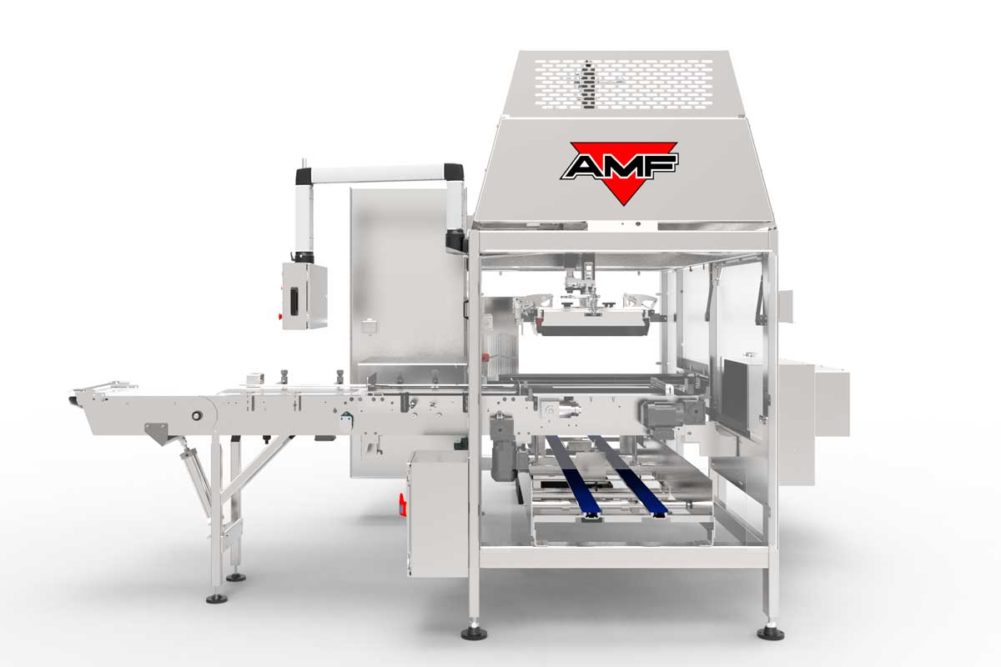

The small-footprint VersaLoader and the ultra-small footprint VersaPak by AMF Bakery Systems use patented servo-controlled gantry robotic arms to deliver tightly grouped product packages into basket, tray or corrugate containers, including U-board insertion. Servo-controlled motions ensure gentle product handling with high-speed capabilities. As part of a complete system solution, AMF’s product loaders are seamlessly integrated through sanitary conveying systems to packaging equipment, basket stacking and unstacking systems, basket washers, dry trash removal systems, corrugate case erectors/case closures and palletizers.

“The systems ensure tightly grouped product packages are delivered safely and efficiently to basket, tray or corrugate containers with minimal footprint and a variety of machine orientations to fit in the most difficult layouts,” said Diana Boxey, global marketing director for AMF Bakery Systems.

The equipment can improve efficiency up to 10% compared with standard product loaders. And the patented quick-change end-of-arm-tool uses 200 small suction cups to pick groups of products while compressing the entire pattern into the basket for a tight package-to-basket fit ration. The end-of-arm-tool moves at high speeds and can execute difficult pack patterns for both wrapped and unwrapped products, Ms. Boxey added.