There’s a wide range of technologies available in today’s industrial world that capitalize on new forms of data visualization. From assisted reality to augmented reality (AR) to virtual reality (VR), it’s easy for a food manufacturer to get lost in it all.

However, the benefits of the applications of AR are clear to see. Alexander Ouellet, innovation engineer for Harpak-ULMA Packaging, outlined the advantages and challenges of incorporating AR into food packaging in a Pack Expo Connects educational session on Nov. 9.

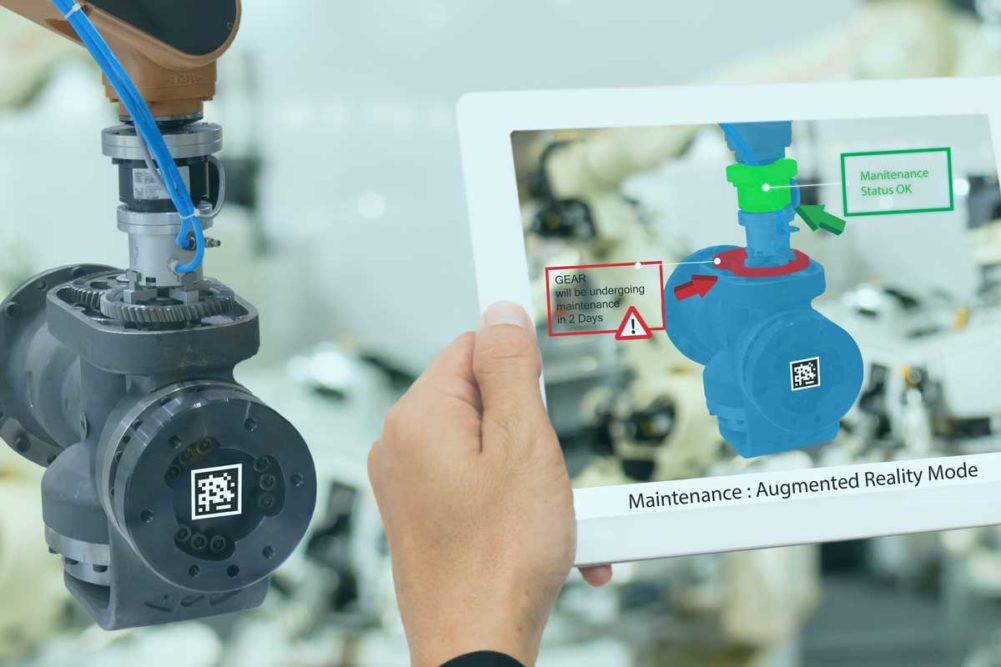

AR enhances the understanding of the physical world by overlaying it with information. This can be done through AR glasses, smartphones or tablets. As opposed to virtual reality, where the user engages in a 100% virtual world, AR manipulates the physical world to display information in an interactive way.

Mr. Ouellet acknowledged that AR is still an immature market, especially in its applications for consumers, but the benefits for industrial applications are making it more widely accepted.

“We believe future AR deployment will be driven primarily by industrial applications because that’s where the biggest bang for the buck lies,” he said. “While the adoption of mobile computing has helped close the gap between working professionals and frontline workers, the gap is still substantial. AR for the first time is bringing computing and on-demand information to our frontline workforce.”

Many frontline operations workers in a bakery cannot switch between a tablet and their task, he explained. They cannot stop what they’re doing to type or ask for digital assistance.

“AR is making it possible to more quickly train or provide expert guidance to a workforce and provide them the information they need at the right time and with the right context,” Mr. Ouellet said.

Beyond the qualitative data of AR, there is also quantitative results. Mr. Ouellet said AR will be able to help operations improve productivity by 30% to 60%, depending on the specific application. Several recent studies and examples have led Harpak-ULMA to make this prediction.

A recent study at Iowa State University showed that it is faster to train people on complex tasks with AR, and that it also virtually eliminated human error in those processes.

One company to implement AR in manufacturing has been Lockheed Martin. It adopted AR to help workers attach fasteners to a space craft. The implementation of AR resulted in 85% reduction in overall training time, more than 90% improvement in task comprehension, and a 40% increase in overall productivity. The company also was able to save $38 per fastener in a program that buys more than 2 million fasteners per year.

“That’s a staggering value proposition,” Mr. Ouellet said.

However, there are significant challenges with implementing AR in a bakery. Those include the infrastructure of a bakery, whether there is WiFi on the production floor, and access to expensive devices. Developers also need good 3-D data to build these programs, and many bakeries simply don’t have that. Because of this, it’s extremely challenging for a bakery to create its own AR experience.

“Building out an AR experience is a new skillset that matches up the thinking of a UX designer with the CAD skillset of an engineer,” Mr. Ouellet said. “A very particular combination not readily available in today’s marketplace.”

So, Harpak-ULMA has decided to help food manufacturers by working with Rockwell Automation and PTC to create a turnkey solution for bakers and food manufacturers.

“Today, manufacturers around the world are recognizing integrated approaches to connectivity and automation controls unlocks unprecedented productivity,” said Blake Moret, chief executive officer, Rockwell Automation. “Together we’re combining our strengths to bring a more connected enterprise to life.”

Mr. Moret said connected Internet of Things (Iot) technologies help reduce total cost of ownership and unplanned downtime on lines.

Jim Heppelmann, president and CEO of PTC, added that bridging the digital divide between office workers and frontline workers is critical because 75% of the workforce is not sitting behind a computer, but rather out on production floors in plants.

“We need to empower those frontline workers with the same types of digital tools to bring digital information out to the frontline,” Mr. Heppelmann said. “AR allows our frontline workers to collaborate, publish and share how-to information mapped onto the real world rather than on the computer screen.”

Immediate applications of AR in a bakery operation include remote service, remote factory acceptance tests and remote training. AR for remote service allows off-site engineers to see what an on-site technician sees to help guide them through a task. The machine gets fixed faster, and the company doesn’t have to pay travel costs. Mr. Ouellet said this application works well for any procedure that requires significant detailed explanations.

“Even when your team is already trained, leveraging AR procedures can dramatically reduce the chance for error by enforcing checkpoints and confirmations that the task was performed to spec,” Mr. Ouellet added.

AR can seem like a daunting technology to deploy. But by taking a targeted approach, Mr. Ouellet said baking companies looking to increase packaging productivity have a lot to gain.

“You really need to have clear goals about what you intend to accomplish with AR,” Mr. Ouellet said. “AR is a great and fascinating tool, but unless we’re solving a specific problem, there’s no hard return on that investment. You need to consider the business use case for each application for the specific problems you’re trying to solve, and laser focus on them.”