When art meets science in a bakery, that’s where true inspiration often begins. In fact, an enormous amount of creativity goes into scientific advances that have led to breakthroughs in oven technology from high-emissive coatings born out of NASA to the latest in digital controls from Silicon Valley.

For artisan bakeries seeking to bring craft breads and rolls to the broader market, the secret to success may lie in the hearth, but other variables play vital roles. Bakers can select from a plethora of options to tailor their baking processes to specific artisan products.

“Crusty French bread, ciabatta and heavy rye breads are all considered artisan, but a baker may choose several different oven types for each product,” observed Phil Domenicucci, baking systems specialist, AMF Bakery Systems.

He added that ovens can be outfitted with multiple configurations of heat, such as direct, indirect, convection and impingement, just to name a few. Some products do best with a dry heat while others require it to be hot and steamy.

“For a hearth-baked, heavy rye bread that requires lots of steam, an indirect-fired oven would be a good choice,” Mr. Domenicucci said. “This oven has thick stone plates as a hearth. It may also include several convection zones. The baker may even request a pre-bake oven combination. These ovens could be heated by electric, natural gas, propane or fuel oil.”

However, it takes a totally different approach to bake an artisan-style, whole grain bread in a pan with lids.

“A direct-fired oven with grids, a steam system and convection would be more suitable,” Mr. Domenicucci said. “This type of oven could be heated with natural gas, propane, city gas and hydrogen.”

Gemini/Werner & Pfleiderer ovens come with precision steaming with the roof, sides and base of each steam zone constructed from 321 stainless steel.

“Targeted steam is delivered directly to the product for minimal waste,” noted Ken Johnson, president, Gemini Bakery Equipment. “Steam quantity and flow direction are variable and manually adjustable. Steam is supplied to both sides of the oven to ensure uniform distribution.”

Moreover, he pointed out the steam zone has bottom heat and no top heat to maximize steam condensation on the product. High-temperature Teflon curtains are placed in the front and back of the steam zone, which also comes with exhaust dampers to retain or eliminate moisture for each product.

To develop the crispy crust texture that defines artisan breads, Topos Mondial relies on cyclothermic heat with either a steel plate or granite hearth.

“The accumulated heat will help create that crust on the bottom of the bread that bakers used to get from their hearth ovens more than 100 years ago,” observed Ondrej Nikel, PhD, director of engineering, Topos Mondial. “You need a hearth that has the capacity to hold a lot of heat for baking these types of bread.”

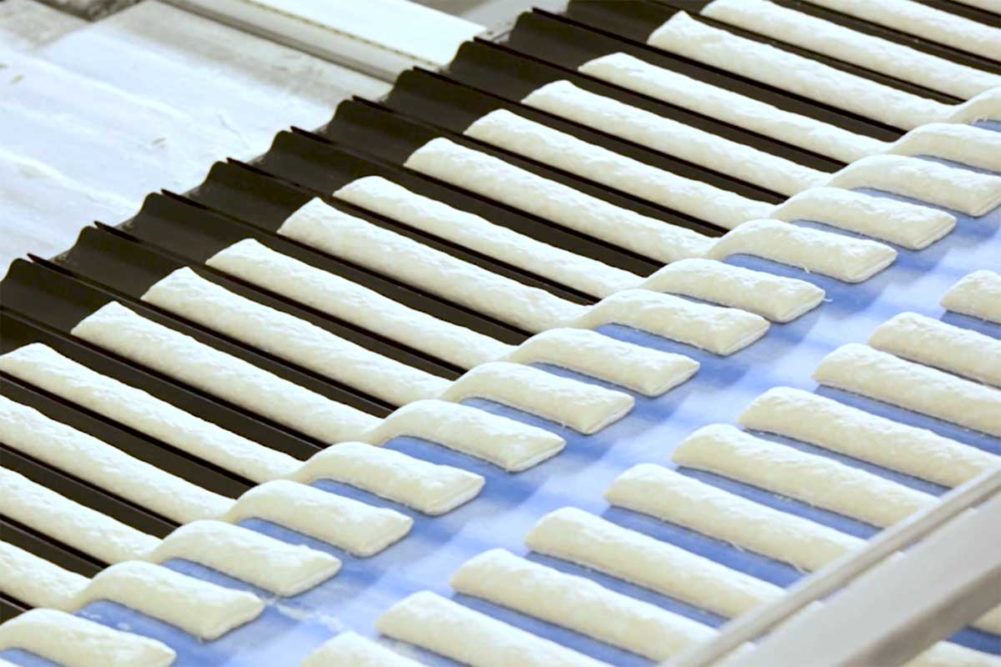

Marie Laisne, product marketing manager, Mecatherm, noted that baking directly on a stone or metal belt hearth creates the oven jump during the initial expansion stage. This establishes the authentic appearance of artisan breads and rolls.

“Hearth baking, combined with a steam intake, optimizes the development of the product,” she said. “Optimal steam intake plays an important role in the production of crispy breads and allows the surface of the dough to soften for superior expansion of the product without the crust tearing and without the product marking of standard industrial breads.”

The final stages stabilize the structure and add the desired color to baked goods.

“It’s equally important to control the thickness of the crust,” Ms. Laisne stressed. “At present, the trend is toward thinner crusts.”

Today’s ovens provide bakers with the opportunity to mix and match both heating and belt type, but such versatility often comes at a cost.

“There are ovens with multiple tunnels, up to six, that offer flexibility but usually for not very high-volume operations,” Mr. Domenicucci said. “With multiple tunnels, it is possible to have different hearths, such as stone, hinge plates and mesh belts, which will allow for different products to be baked on different belts, but the overall capacity is reduced.”

He added that bakers can choose from steel, cast iron and hinge plates to hundreds of different mesh belts to meet often highly specific product specifications.

A Gemini/Werner & Pfleiderer indirect-fired tunnel oven may come with a friction drive mesh belt, chain-driven stone plate belt, chain-driven steel plate belt or an open-sprocket-driven grid belt for pan products.

“Each belt in conjunction with bake profiles will provide for different crumb textures from dense to open and crust characteristics from thin and crispy to thick,” Mr. Johnson said.

Dr. Nikel noted test runs typically determine the hearth of choice.

“We had a pizza maker who wouldn’t want it any other way except to bake on a granite surface,” he said. “There are also marketing benefits by declaring on your packaging that the products were baked in a stone hearth oven, even though you have a very automated process.”

Additionally, Ms. Laisne said, belt type determines the artistic appearance of artisan breads.

“The coating of the belt, whether it’s stone, metal or woven mesh, impacts the kinetics of the energy input to the product,” she explained. “Baking on a thin, wire mesh belt allows temperatures to be adapted quickly thanks to low inertia, while stone baking reinforces, for example, the storytelling around an authentic baking process.”

This article is an excerpt from the September 2021 issue of Baking & Snack. To read the entire feature on Ovens, click here.