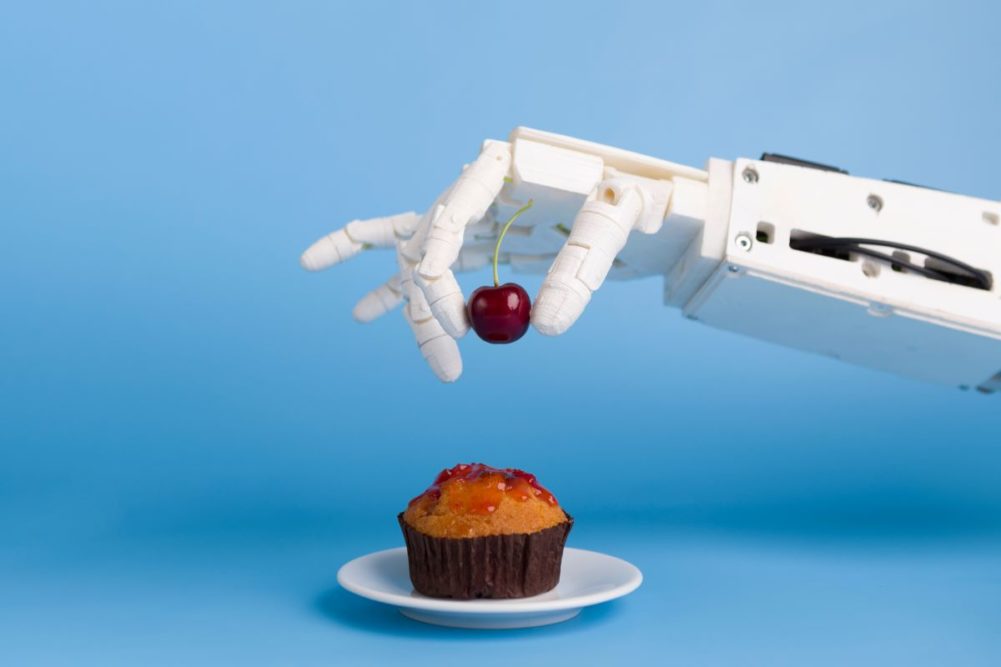

KANSAS CITY — When it comes to working in a bakery, manual tasks can make for a long, dreary day — and it’s the perfect environment for creating a high-turnover workforce. That’s why robots and cobots are becoming increasingly popular in the food industry.

Five years ago, greater efficiency and higher capacity were the most important drivers for robotics in the packaging arena. During the past three years with COVID-19 disruptions, the focus has been on overcoming labor challenges. Such emphasis on labor also has affected the way bakeries calculate return on investment (ROI).

Baking & Snack’s April report on robotic technology noted that many companies have slightly extended their payback timeline due to labor shortages while others are factoring in lost revenue and profit when lines aren’t adequately staffed for full or partial shifts, which can dramatically impact the ROI equation. Today’s ROI formulas now include the weighted cost of employees along with the inability to produce enough snacks or baked foods because of workforce woes. Industry experts suggest bakers are highly focused on the ability to run at capacity without needing to rely on the unpredictable availability of human labor.

Robotics provide accuracy and repeatability leading to higher reliability, less waste and less downtime. They also reduce direct human contact with food, decreasing contamination risks. That said, limitations include not being able to adapt to changes in packaging sizes, product shapes and other unforeseen variables not preprogramed in the robotic system.

Bakeries need to determine what works best for them in both the short and long term.