Working with allergens like wheat, nuts, eggs and dairy, cookie makers face the added obstacle of ensuring a sanitary operation while minimizing cleaning times and product changeovers.

“Newer designs are built for increased sanitation and reduced time to sanitize equipment,” said Kevin Knott, technical sales manager, Bühler Group.

Mr. Knott recommended buying a second depositing head for faster changeovers, allowing bakers to clean one head while still producing with the second one.

Similarly, John Giacoio, vice president of sales, Rheon USA, said the company can supply bakers with a second set of the food zone assembly, called a “hot swap” changeover set.

“With this ‘hot swap’ option, an entire section of the machine that is in the food zone is pulled out as one piece and a second set is inserted in minutes, he said. “This then gives the bakery time to clean the first set so it is ready to go at the next changeover.”

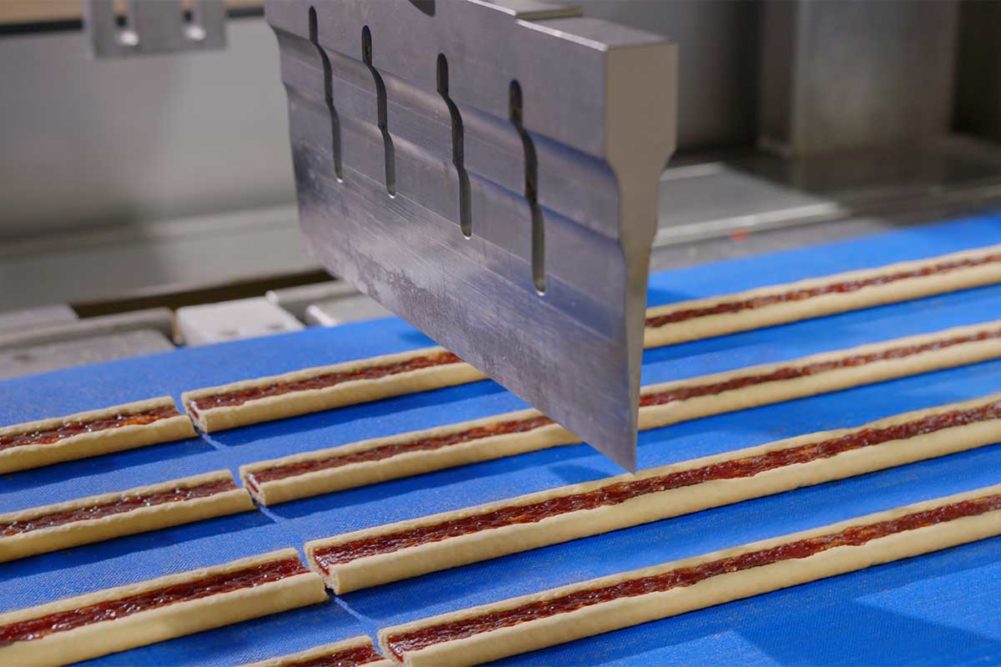

He added that Rheon’s co-extrusion equipment for filled cookies is designed so that food zone parts that come in contact with product can be removed easily.

“With this in mind it only takes a fraction of the time to do a complete changeover to a different product,” he said.

A more efficient sanitation process can also be achieved with machinery designed for toolless operation, said Sam Pallottini, director of biscuit, cookie, pet food sales, Reading Bakery Systems (RBS).

“For example, an internal belt circuit for a wirecut can be removed and replaced in 10 to 15 minutes without any tools,” he said. “The same is applied to removing the extraction webbing for a rotary moulder.”

RBS’ WCX wirecut, he noted, can be removed and carted to the washroom without the need for an overhead hoist.

Other sanitation features for cookie production include standoffs to prevent debris collection and sloped top enclosures for easier washdown, added Mark Glover, product manager for baked products & food extrusion, Baker Perkins, both of which are part of the company’s TruClean standard. Belt changeover speeds have also been improved.

“Belt changeover prior to TruClean could be time consuming, but Baker Perkins’ utilization of a universal pulley drive arrangement versus a direct drive allows the operator to quickly change out the endless belt, drastically reducing downtime for sanitation or product changeovers,” he said.

This article is an excerpt from the April 2023 issue of Baking & Snack. To read the entire feature on Cookie Processing, click here.