By their very nature, emulsifiers bring a wealth of functionality to baked goods across all applications.

“Emulsifiers help bring nonhomogenous mixtures together; as a result, they play critical roles with blending and help ensure consistency,” said Dave Lindhorst, technical services manager, Cargill.

Blending nonhomogenous mixtures — think blending oil and water — is critical in applications like icings, fillings and batters. But emulsifiers’ roles go beyond basic blending and bring their benefits to applications like bread, buns and rolls as well.

“Emulsifiers provide strength and stability to doughs and batters,” said Matt Keyser, Northeastern sales, Brolite Products. “They can also provide increased shelf life, possibly allowing for longer runs and fewer changeovers. Lastly, they can provide better processing, allowing for less waste and more uniform product.”

One of emulsifiers’ greatest contributions to breads, buns and rolls is their ability to strengthen them against the automated production process and maintain product softness. While conventional emulsifying solutions may have an uphill battle against the clean label movement, technology has improved to provide bakers clean label alternatives, too.

“With consumers demanding a decreased use of food additives, it’s important to understand why some of them are utilized so often in the food industry,” said Tim Cotrell, North America director of business development for emulsifiers, texturants and acacia, Kerry. “Emulsifiers and their food functions allow the consumer to enjoy baked goods without quality defects and any number of negative sensory defects. These serious defects include being tough, dry, stale or tasteless.”

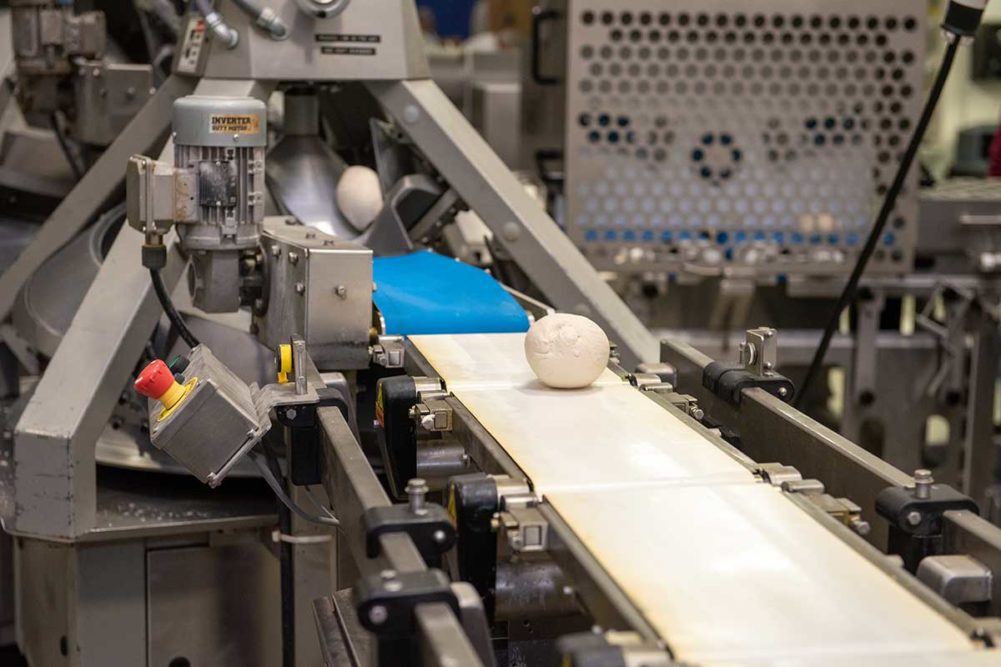

As baking companies have invested heavily in more automated production lines the past few years — either due to increased capacity needs, reduced labor or both — the quality of bakery products not accustomed to so much processing could be affected.

“With more automation added into bakeries, the formula robustness is critical to ensure that a quality product is delivered,” said Yanling Yin, PhD, director of research, development and applications for bakery at Corbion. “There are some emulsifiers — SSL, DATEM, ethoxylated mono- and diglyceride, for example — that would be able to enhance dough strength going through the process to maintain product acceptable attributes of volume, texture, etc.”

While some equipment manufacturers have come a long way in minimizing automation’s impact on finished product quality, sometimes bakers can see a negative impact on both volume and crumb structure.

“An increase of automation will often bring an increase in ‘shock’ to the loaves,” said John Nedderson, principal designer for bakery and fats and oils group, IFF. “Shock occurs when the loaf is physically disturbed in some way like when a loaf pan hits the end of a conveyor. This shock leads to a decrease in loaf volume. Some dough conditioners, like DATEM (or diacetyl tartaric acid esters of monoglycerides), are very effective at minimizing the volume loss when bread is shocked.”

These shocks can even include the vibrations from the conveyor, said Cam Suarez-Bitar, director of marketing and public relations, Pak Group NA. It’s the emulsifiers’ binding properties that strengthen the gluten matrix against these forces.

“Emulsifiers’ binding properties help mitigate these variables, since they help maintain the dough’s overall strength,” he said. “They also improve texture and crumb structure, and contribute to the finished product’s shelf life.”

Not only do emulsifiers strengthen the dough, but they can also soften it and deliver the crumb structure consumers expect from their loaf of bread.

“Emulsifiers tend to strengthen and soften dough without making it significantly tighter. This means the dough goes through machinery more easily with less stress,” said Troy Boutte, PhD, vice president of innovation, AB Mauri North America. “Emulsifiers do this by providing lubrication and forming complexes with the two main fractions of dough, which are starch and protein.”

Strengthening and softening not only protect the dough from the shocks of automation, but they also ripple into other desired effects on the finished product.

“Emulsifiers help improve dough machinability while promoting better gas retention, crumb structure and volume, resulting in a more consistent product,” said Sherrill Cropper, PhD, new product development lab manager, Lesaffre. “In addition, some emulsifiers can help enhance short-term softness. If you use automation, it’s also likely that extended shelf life is something you’ll need for distributing large batches.”

The dough itself can also clash with equipment. Stickiness and diminished elasticity can make it difficult to machine. Emulsifiers can address both issues.

“They also reduce dough stickiness, making it more machinable and even preventing dough tearing as it goes through the automated process,” Mr. Lindhorst explained. “From beginning to finished product, a bread dough must withstand a lot of abuse — it’s pushed, pressed, chopped and ultimately sliced — emulsifiers can help maintain product consistency.”

In addition to improving the way dough moves through the machinery, emulsifiers can improve process efficiencies by eliminating some steps.

“Emulsifiers are used as part of a solution to maintain the baking quality of bread that can go directly from freezer to proffer by removing the dough retarding step,” Mr. Cotrell said. “Usually bakers would retard dough for 10 to 12 hours. By removing this one step we are automatically reducing the production process from an estimated 15 hours down to 2.5 hours.”

Not only does this save bakers time but it also increases frozen dough shelf life while improving dough tolerance and stability.

Consistency is the final piece to the automation puzzle. Automation allows baking companies to accelerate production while maintaining quality. Its repeatability and speed are its strengths. However, without consistent dough coming out of the mixer, automation cannot reach its full potential.

“As baking facilities integrate more automation, the consistency and predictability of the dough become increasingly crucial,” said Mark Zielonka, national R&D product specialist, BreadPartners. “Emulsifiers play a key role in maintaining these factors.”

Each emulsifier, conventional or clean label, provides its own set of functionalities that can ensure a bread dough withstands the forces it will encounter throughout the production line. That’s why it’s critical to choose the right one.

This article is an excerpt from the July 2023 issue of Baking & Snack. To read the entire feature on Emulsifiers, click here.