Don’t create a problem while trying to solve another one. In the world of sanitation, the law of unintended consequences can create a bigger mess that takes longer to clean up or possibly creates a serious food safety issue that could have been easily avoided.

That’s why sanitation managers constantly remind their employees to avoid making mistakes that do more harm than good.

“The most common ‘no-no’ that I observe are practices that can cause sanitation to become a source of cross-contamination,” said Nathan Mirdamadi, food safety manager, Commercial Food Sanitation, an Intralox company.

Those acts involve using compressed air to relocate — rather than clean or remove — allergens, or taking cleaning tools designated for wet cleaning and using them in dry clean areas.

“Floor scrubbers, if not managed properly, can actually be the vector of contamination,” he noted.

Instead of using compressed air to clean, vacuuming and brushing overhead pipes and conveyors are much safer and effective, suggested Bret Zaher, manager at AIB International.

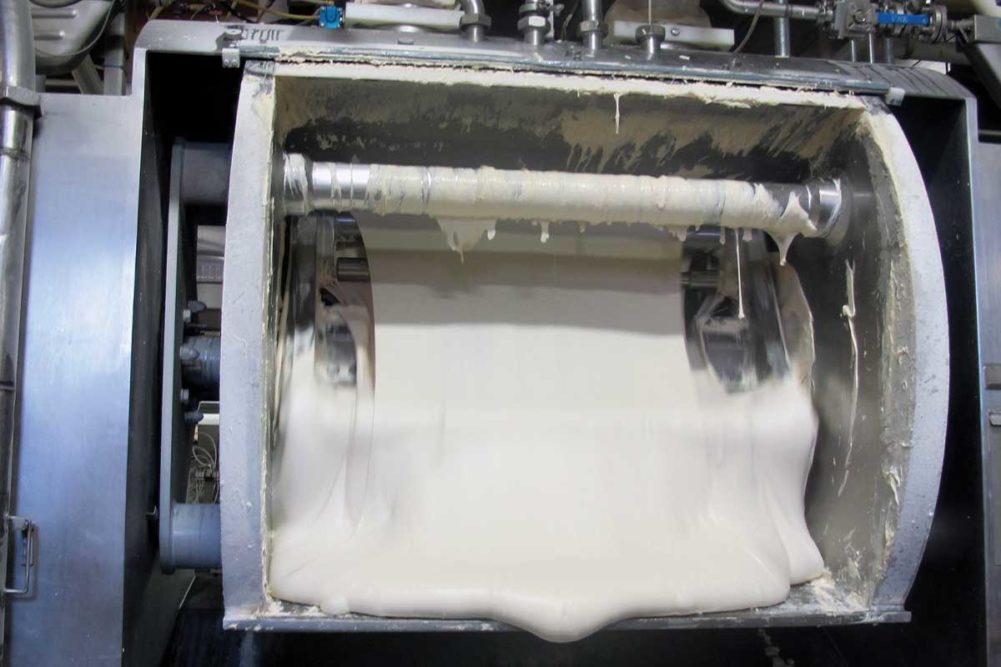

Additionally, he said, don’t use water to clean cloth belts. That’s because it takes a very long time to properly dry, and the cloth belts are often still damp at the start of production. It can also result in mold development directly in the product zone.

“Last, but not least, a line should not be cleaned while the one next to it is running,” Mr. Zaher said. “Often, allergen cross-contact issues or cross-contamination occurs even if barriers are put in place to help prevent it.”

This article is an excerpt from the October 2023 issue of Baking & Snack. To read the entire feature on Sanitation, click here.