| Sign up for our free newsletters From breaking news to R&D insights, we’ll send you the top stories affecting the industry. |

Subscribe |

Already a familiar name supplying turnkey processing and packaging solutions to several industries, IMA focuses on the food sector through one of its best-established clusters known as IMA Flexible Packaging hub, whose expertise in flexible packaging solutions covers the current and future needs of the bakery sector.

However, being a well-known player is far from the objective IMA has set itself in order to keep pace with a market that evolves rapidly from one year to the next. In fact, IMA FLX is investing substantial resources into cutting-edge technologies and new machines that will attract the forward-looking manufacturers, those who intend being the key players in this industry over the next decade and more.

Today, IMA FLX is made up of different brands whose integrated experience and variety of solutions have given rise to the most comprehensive flexible packaging hub serving the bakery sector. Driven by IMA Group’s company culture that pioneers sustainability in every aspect of business or technology, IMA FLX represents a one-stop supplier that is best-placed to support bakery manufacturers looking to deal with tomorrow’s trends as leaders in their own market.

IMA FLX’s team of specialists take great pride in their many years of hands-on experience in the bakery industry. This field-tested know-how is expertly applied to the wide range of reliable, flexible, and innovative packaging machinery and complete automatic lines designed and manufactured with bakery industry requirements in mind. IMA manages your product from the oven/freezer exit to handling, feeding, dosing, primary, secondary, and end-of-line packaging.

From fresh cakes, bread and pizza to biscuits, frozen dough and prebaked products, each application has its own unique packaging requirements and the IMA FLX hub companies - IMA Ilapak, IMA Delta Systems, IMA Record and IMA Eurosicma - offer the best solution for each of these applications, customized when needed. With such an array of competences, the bakery sector can rely on this cluster of expert brands to deliver a turnkey solution which will enhance performance and bring the customer a competitive edge.

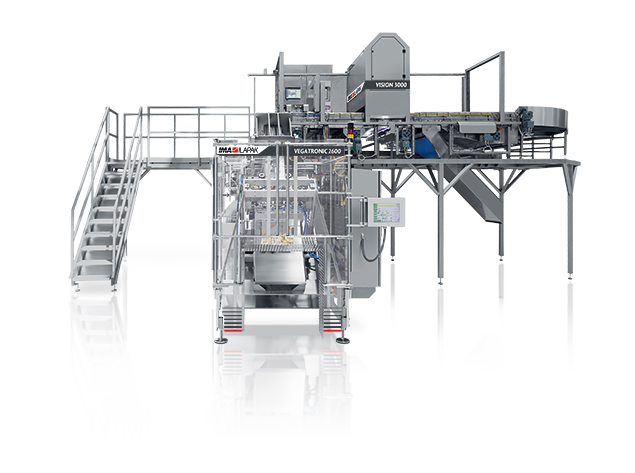

IMA Ilapak vision systems using laser technology or multi-head weighers coupled with IMA Ilapak VFFS vertical baggers. Together, as a fully integrated solution for bakeries, these machines represent the ideal solution for a complete bagging line for fresh, par-baked, frozen, and raw dough products, whether baguettes, pretzels, rolls, bagels, donuts or croissants.

The vision systems or multi-head weighers feed the Vegatronic bagging machines equipped with film buffer, an exclusive feature to avoid downtime. According to product and gentle handling requirements, the bagger can operate with 30, 45 or 60-degree inclination. Small or large bags can be used to pack fresh or frozen rolls, croissants, bagels, muffins and more. Flexibility is enhanced thanks to solutions increasing line efficiency and features designed to facilitate changeover procedures and minimize downtime, such as the film buffering function allowing the film roll to be changed without stopping the machine.

Source: IMA Ilapak & Paolo Toscani

Source: IMA Ilapak & Paolo ToscaniCompleting the benefits of Vegatronic series, the open-frame design offers easy access for fast maintenance, and boasting the highest seal pressure on the market, gas tight seals are fully guaranteed.

The Delta series from IMA Ilapak is one of the best-known ranges of flow wrapping machines on the market offering M.A.P, hermetic sealing and hygienic design.

In view of a growing trend towards sustainable packaging materials, typically hard to handle, containing high proportions of paper or recyclable mono-material, plastic based on PE or PP, the Delta range thanks to its long-dwell sealing capabilities covers several new materials and enables companies to be well prepared for the future.

Source: IMA Ilapak & Paolo Toscani

Source: IMA Ilapak & Paolo ToscaniThe Delta series, when coupled with the VACMAP™ system, ensures the same shelf-life standards as thermoforming solutions, but with considerably lower costs. Film is less expensive and minimal operator intervention keeps labour costs to a minimum, even when changeover is performed. Furthermore, less material is used by a flow wrapping platform than a thermoforming solution, thus placing less wrapping film/material on the market and consequently in the environment. Higher throughput and exceptional flexibility are hallmarks of the Delta combined with VACMAP™ as it easily handles multiple sizes compared to thermoforming technology.

IMA Ilapak flow wrappers, integrated with the VACMAP™ system, represent a valid and cost-effective alternative to thermoforming solutions, combining vacuum and modified atmosphere packaging (M.A.P.) in a single solution.

Sustainability is a common topic across a broad variety of industries, even more so when it comes to the food packaging sector. In an effort to support companies needing to achieve ambitious targets and lay claim to a sustainable approach, IMA has dedicated significant resources to researching innovative packaging solutions.

Originally established in 2016 at the IMA Ilapak facility, OPENLab is now a network of laboratories and testing areas with different locations within the IMA Group: new materials are first investigated in a high- tech laboratory and then tested on fully working packaging lines. Extensive trials are enabling IMA Ilapak to help industry players and prepare tangible solutions to meet current and future needs in terms of sustainable packaging materials, continually influenced by an evolving legislative scenario.

Focusing on flexibility as a rewarding strategy, IMA Ilapak has been able to adapt its packaging solutions and give its customers a competitive advantage. Long-dwell sealing solutions are by far the most interesting for the future of the sector, even if not all of today’s regulations insist on sustainable packaging materials. Such sealing technologies will undoubtedly be essential within a few years, making the investment a sensible option today.

As the need to eliminate preservatives in advanced markets increases, replacing standard technologies with M.A.P. systems, IMA FLX is well placed to offer a variety of alternative packaging solutions, from simple and essential machines to sophisticated, customized lines.

Want to learn more? Visit https://www.ilapak.com/

| Sign up for our free newsletters From breaking news to R&D insights, we’ll send you the top stories affecting the industry. |

Subscribe |

Check out highlights from SupplySide West held Oct. 28 - 31 in Las Vegas.

Five manufacturers and suppliers were issued patents.